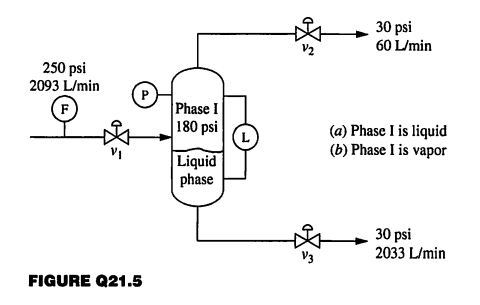

Two physical systems with exactly the same equipment structure, pressures, and flow rates in Figure Q21.5 are considered in this question. The only difference is that in system (a) phase I is a liquid (this is a decanter), whereas in system (6) phase I is a vapor (this is a flash drum). You may assume that the flows are proportional to the square root of the pressure drop and the valve % open; the valves are all 50% open at the base-case conditions. The three valves are available for manipulation, and three controlled variables are shown as sensors. The following additional information is provided about the variability of the process operation: the feed flow is 1400 to 2600 L/min, the percent overhead material in feed is 1 to 5%, and the external pressures are essentially constant. Select the best control loop pairing and discuss the differences, if any, between the results for systems (a) and (b).

#Sales Offer!| Get upto 25% Off: