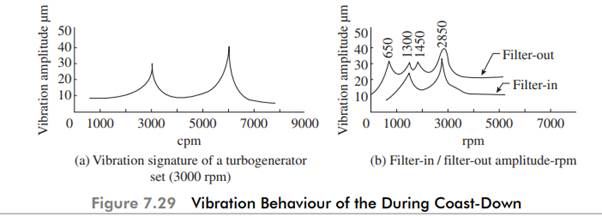

It is extremely important to note and remember that in each of the example discussed in the previous paragraphs, the recorded vibration amplitude occurred at the rotating speed frequency (1 × n) of the machine. However, these plots alone may not reveal the system response to other vibration frequencies which can affect the overall machine performance from the vibration point of view. To illustrate this, consider the amplitude-versus-frequency signature of a typical TG set operating at 3000 rpm as shown in Fig. 7.29(a). In this instance, the TG has two significant exciting frequencies, that is, 1 × n due to, perhaps, unbalance and another at 2 × n (6000 rpm), probably due to misalignment. In this typical case study, the TG rotor has critical speeds (resonant frequencies) at 1300 and 2850 rpm.

Obviously, when TG coasts down in speed, the unbalance at 1 × n will excite the resonance when the speed falls down from 3000 rpm (at the instant machine is tripped) to 2850 rpm. In addition, as the TG continues to run down, the resonance will once again get excited when the speed reaches 1425 rpm on account of 2 × n excitation caused by misalignment (of connected rotors / bearings). This excited resonance will not appear in the bode plot at 1425 rpm because the analyser filter is tuned to 1 × n and rejects all other frequencies. Because the filter-in amplitude versus rpm plot (a part of bode plot) does not always give a complete picture of the total system response, it is customary to obtain tow plots of amplitude versus rpm, one filter in, synchronized to 1 × n (conventional bode plot) and second (filter-out) overall amplitude-versus-rpm plot as shown in Fig. 7.29(b). These plots are of great value in ascertaining the nature of distress in the machine.

It is, from this point of view, very important to identify the critical speeds, nature of balance, and alignment condition of the machine at the time of commissioning of the machine through bode plots and also filter-in / filter-out vibration-versus-rpm plots as shown in Fig. 7.29(a) and b. These plots can be used as reference plots for the purpose of condition monitoring of the machine. Any departure from the reference plot indicates a deteriorated condition of the machine and hence, the operator can carry out a preventive maintenance to avoid catastrophic failures. We shall, in the forthcoming sections, discuss a case study where the catastrophic failure of a large steam turbine—generator could be avoided by comparing the bode plot and filter-in / filter-out versus rpm plots of the operating machine with reference plots.