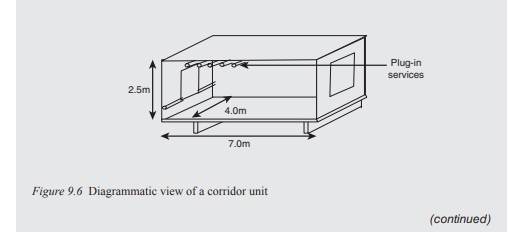

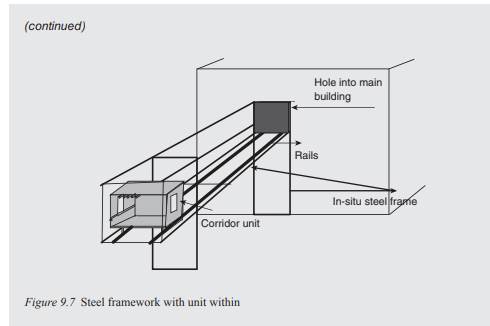

The Superior Product Team was set up as a consortium of contractors, designers and the client to provide completed corridor units that fit inside a structural steel frame. Each prefabricated unit weighed 6.8 tonnes and was 4m long, 7m wide and 2.5m high. The units could be double-stacked or divided into two narrower corridors 3.5m wide (Figure 9.6). Each unit was externally cladded and glazed to provide a finished waterproof product bolted within the onsite in-situ steel frame. The units were complete with modular plug and fix heating, electrical and IT services. The steel frame was standalone and configured to the route of the corridor, which generally linked two buildings. In order to install the units within the frame, rails were fixed to the frame at the height of the floor and units were lifted into the frame by leaving out a section of the top frame structure (Figure 9.7). Units were lowered onto the rails and pushed along them until they met up with the last corridor unit; they were then sealed, bolted together and connected to services. This action was repeated for each corridor unit in both directions up to the access holes in the steel frame. Tolerance was critical, allowing the steel to be slightly out of true longitudinally; however, high tolerances were required on the rail level and the plumb of the structural columns to which the units were bolted top and bottom. Once a corridor was completed between the two buildings, the services could be hooked up, tested and commissioned.