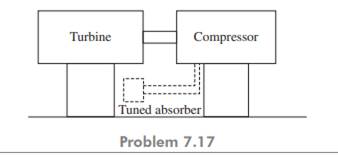

A turbine-driven compressor (shown in figure below) operates in the speed range of 2000–4000 rpm and usually it runs around 3000 rpm. The vibration behaviour at and around 3000 rpm is extremely rough despite achieving a very high degree of balancing of both the turbine and compressor rotors done in the balancing tunnels of the manufacturer. The vibration-spectrum analysis done on the unit ruled out the possibilities of vibrations arising due to misalignment and other possible defects in the assembly of the unit. It was therefore decided to use a tuned absorber to reduce the severity of vibration on the turbine-compressor unit. The proposed tuned absorber is a cantilever beam carrying a mass of 20 kg. The absorber natural frequency is adjusted to 3000 rpm. Find the natural frequencies of the assembly. Assume the mass of turbine-compressor assembly as 1000 kg.